Analysis/Simulation

The Computer Aided Engineering Group draws on analytical tools such as for structural analysis, fluid analysis, and simulations to solve problems and perform optimal designs for our products and processes.

- Analysis

- Structural analysis

- Fluid analysis

- Simulation

- Process simulation

- Noise simulation

Analysis

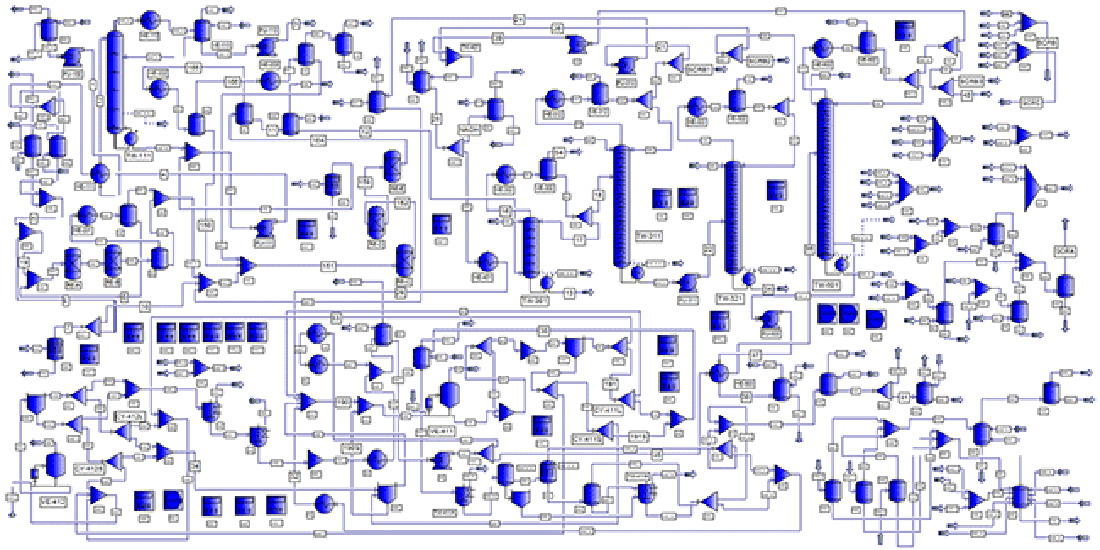

Structural analysis

The finite element method (FEM) is used to analyze topics such as stress, deformation, temperature, and dynamic response to loads on equipment such as weight and temperature.

- Main fields and functions

-

- Linear static analysis

- Nonlinear static analysis (materials, geometry, and contact)

- Dynamic analysis (eigenvalues, frequency response, and time history response)

- Fatigue, buckling, and heat transfer analysis

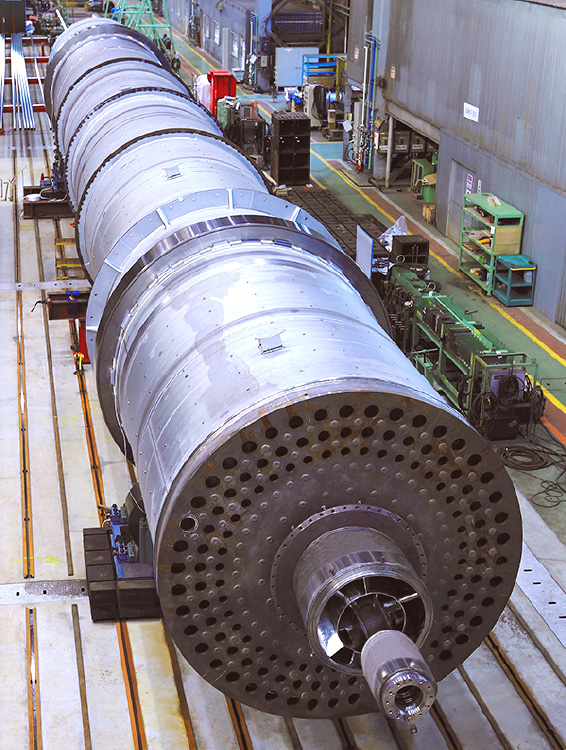

Fluid analysis

The finite volume method (FVM) is used to analyze distributions of gas or liquid velocity, pressure, and temperature inside equipment, dust trajectories in exhaust gas, liquid flows caused by air diffusers, and gas cooling by spraying.

- Main fields and functions

-

- 3D/2D (plane, axial symmetry, and axial symmetry + swirl considered)

- Steady/unsteady

- Compressible/incompressible

- Laminar/turbulent flows

- Newtonian/non-Newtonian fluids

- Heat conduction, convection, and radiation

- Porous medium, multiphase flows (gas-liquid, solid-gas, and solid-liquid), and chemical species

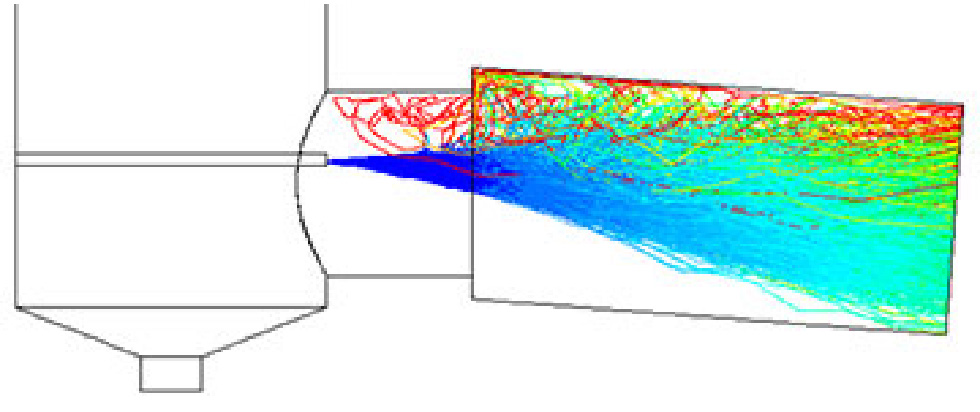

Simulation

Process simulation

Material and heat balances are simulated to develop new processes, study optimization and energy conservation for existing processes, and review plant design specifications.

- Main fields and functions

-

- Software incorporating physical property databases and physical estimation methods

- Steady/unsteady calculations of organic substances, including petrochemical materials

- Steady calculations of electrolytic substances

- Calculations of unit operations, such as distillation, reaction, and solid-liquid separation

Noise simulation

Acoustic simulations are conducted to predict and calculate how noises are generated by engines, pumps, and other equipment are propagated in the surrounding areas of various types of plants.

- Main fields and functions

-

- Calculation methods: Construction noise prediction model (ASJ CN-Model 2007), ISO 9613 Part 1/Part 2, etc.

- Input functions: Loading topographic data

- Output functions: Graphing noise contours on horizontal and vertical planes, graphing changes before and after noise reduction measures, 3D drawings of facilities