Industrial Business: Technologies (Product Categories)

- Distillation

- Crystallization

- Centrifugal separation

- Filtration

- Drying

- Incineration

-

Weighting

/mixing - Storage

- Vibration

- Molding

- Milling

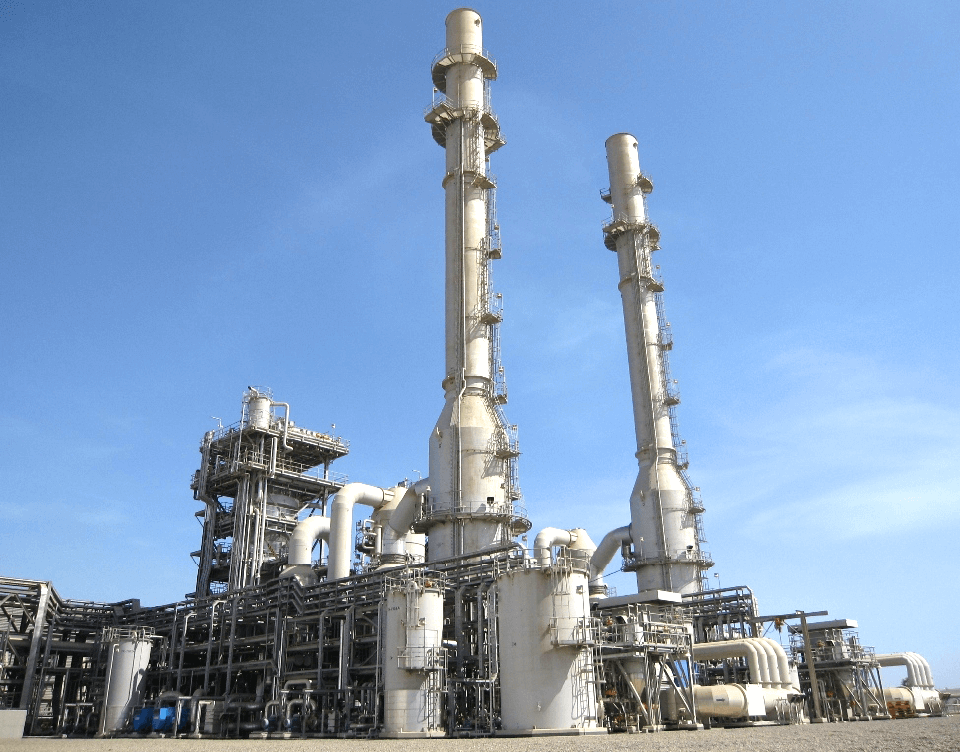

Distillation

Distillation

Tsukishima Kikai’s distillation technologies are used in distillation processes at chemical plants and other facilities.

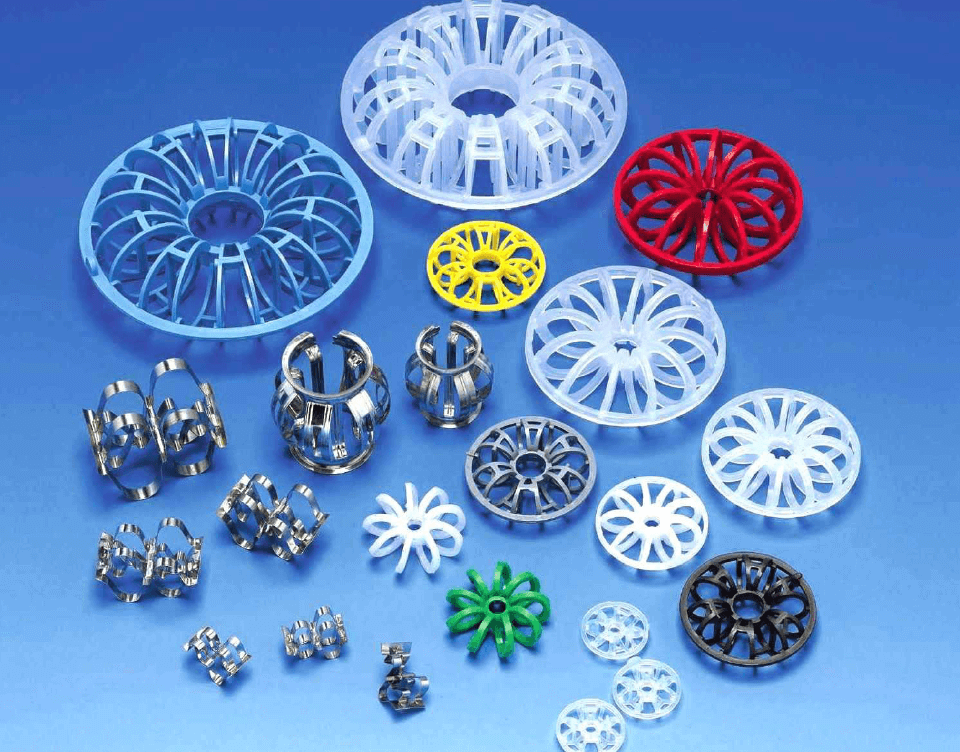

Packing

(Tsukishima Kankyo Engineering Ltd.)

Crystallization

Crystallization

Tsukishima Kikai’s wide-ranging product lineup, including unique DP crystallizers developed in-house, offers crystallization and refining equipment optimized for the specific properties of individual materials.

Crystallizer

(DP Crystallizer / Oslo Crystallizer)

VIEW MOREWe offer solutions for crystallizing processes based on our extensive experience with DP Crystallizer / Oslo Crystallizer developed by us.

Vortex Flow Crystallizer

CRYSTALLEX Type-VF

Ideal for single micron size particle manufacturing. Offers space savings, lower power consumption, and higher yield rates compared to agitation tank types; allows easy scale-up.

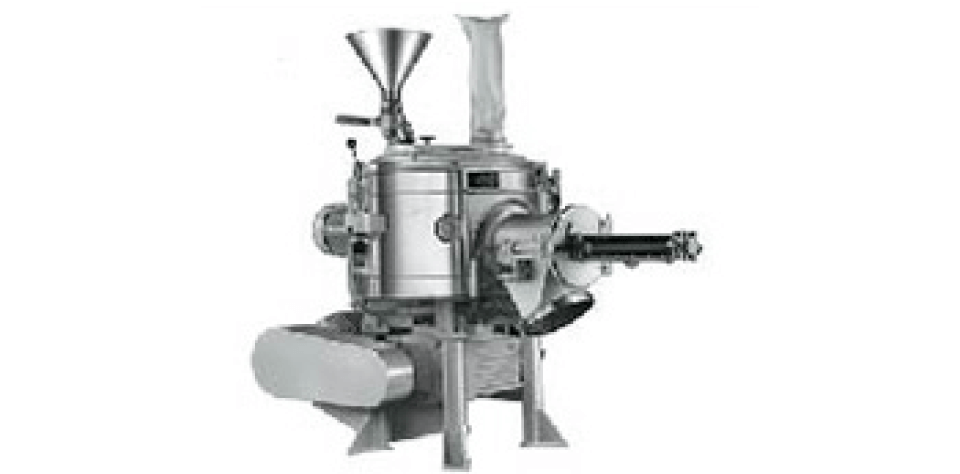

Centrifugal separation

Centrifugal separation

Tsukishima Kikai’s centrifugal separation technologies are used in a wide range of fields including chemicals and foodstuffs. Tsukishima Kikai offers a choice of models optimized for the specific properties of individual materials.

Escher Wyss Push

Type Centrifuge

Continuous centrifuge which can process large capacity, achieve low moisture content as well.

Fully Automatic

Batch Type

Centrifuges

More than 1,000 units of the batch type centrifuge have been shipped worldwide, primarily for use in the sugar refining industry.

Filtration

Filtration

Tsukishima Kikai offers a broad lineup of filtration equipment that play key roles in numerous industrial fields, including chemicals, foodstuffs, and iron and steel.

Horizontal Belt Filter

Continuous vacuum filter unit designed specifically for cake washing performance.

Compression Blow

Dehydrator

Compression blow dehydrator is secondary dewatering system which combined with Horizontal belt filter.

BoCross Filter

Dynamic cross-flow filter unit. Allows high-speed filtering and high concentrations of sub-micron and nano particles.

Filtering and Drying

Machine

Allows full batch processing of filtering, washing, and drying inside a single rotating tank.

Tsukishima Tray Filter

Helps improve cake washing and product yield; achieves relatively low processing volume substance filtering and efficient cake washing.

Tsukishima Precoat Filter

Helps improve product yield, particularly for applications that require a clear filtrate; ideal for treatment for which filtering presents difficulties.

Tsukishima Drum Filter

Helps improve cake washing and product purity; can be used across a wide range of applications; reduces plant costs.

Tsukishima Belt Filter

Helps improve cake washing and product purity; can be used across a wide range of applications; reduces plant costs.

Filter Press

We offer a wide range of equipment, including simple pressure filter systems, compression filter systems, low pressure to high pressure filter systems, systems ranging from small-scale experimental equipment to large-scale plants, as well as manual, semi-automatic, and fully automatic types.

Screw Press

Offers outstanding dehydration performance, energy savings, low maintenance costs, compact dimensions, and low machinery costs. We offer optimal solutions based on an extensive track record and more than 500 units sold.

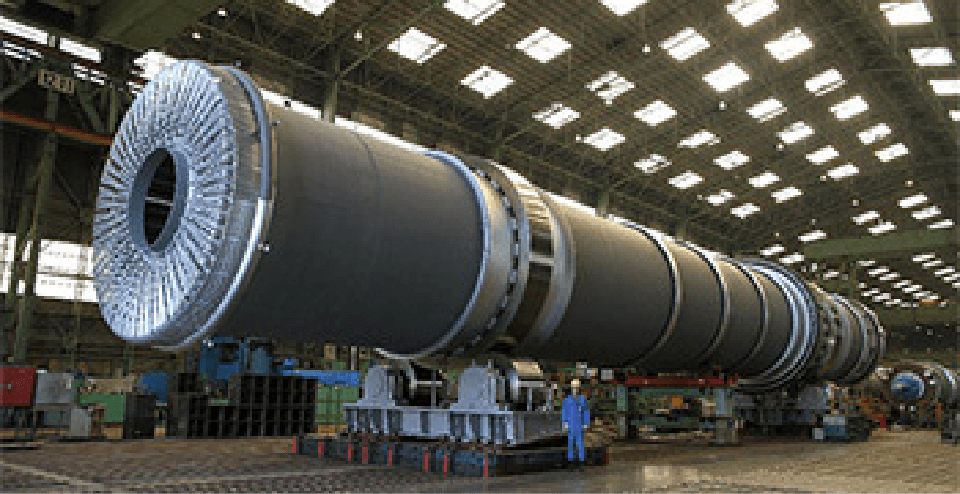

Drying

Tsukishima Kikai’s drying technologies are widely used in fields ranging from chemicals to foodstuffs and the environment.

Steam Tube Dryer

Rotary dryer, ideal for large-volume processing. Over 500 units shipped for a broad range of materials, including coal and chemicals.

Inclined Disc Dryer

Grooved agitation dryer features a special disc construction, making it ideal for highly adhesive materials. Has an extensive track record in sludge treatment.

Fluidized Bed Dryer

Harnesses heated gas to heat material by fluidization. Allows concurrent use with heating element.

Hopper Dryer

Upright type ventilation dryer suited to materials requiring longer retention times. Has a proven track record in final drying of pellets and other materials.

Clean Flash Dryer

Compact vortex-type pneumatic conveying dryer provides ease of maintenance. Can be connected directly to an Escher Wyss push type centrifuge.

T-Type Dryer

Grooved agitation dryer features low-shear disc for minimal material fragmentation. Concurrently uses fluidized gas for high thermal efficiency. Has a proven track record in drying and cooling crystalline and other materials.

Vacuum Mixing Dryer

Batch-type powder mixing dryer. Supports operations such as drying, low temperature drying, solvent recovery, heat treatment, and sterilization.

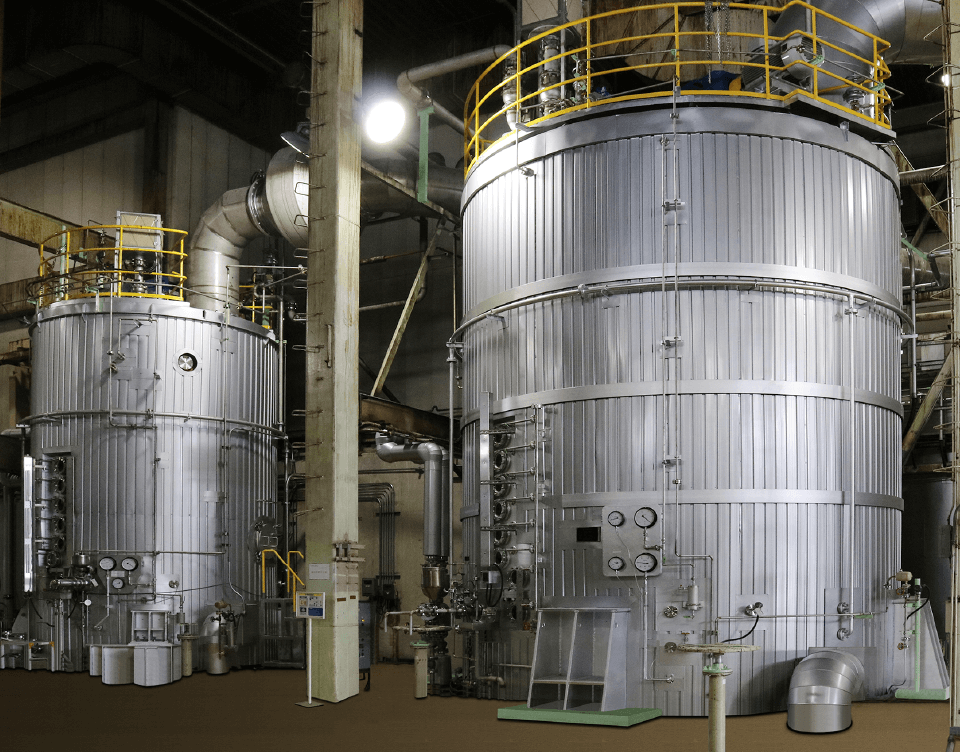

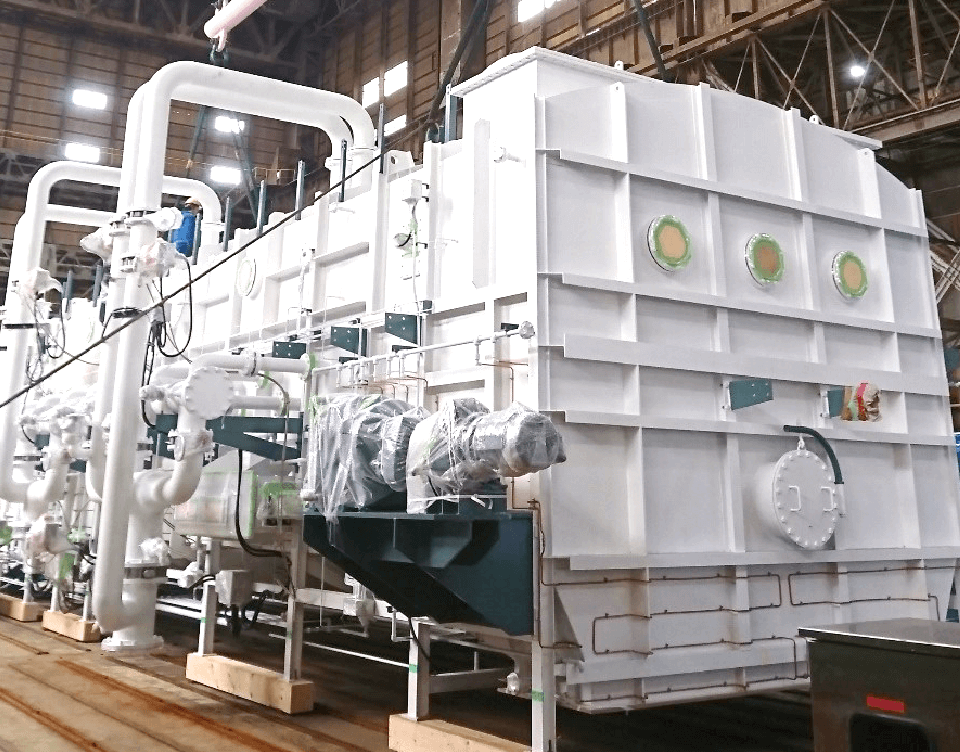

Incineration

Incineration

Tsukishima Kikai’s incineration technologies meet a wide range of industrial needs.

Wastewater

Incinerator

(Submerged Combustion System)

VIEW MORE(Tsukishima Kankyo Engineering Ltd.)

Kiln Gasification System

(Tsukishima Kankyo Engineering Ltd.)

Acid recovery and

Concentration System

(Tsukishima Kankyo Engineering Ltd.)

Weighting/mixing

Weighting/mixing

Mixing

Drawing on expertise gained from our technical alliance with MTI of Germany, Tsukishima Kikai provides mixing equipment with applications across a broad range of fields.

Universal Mixer

Batch-type powder mixer; multi-purpose mixer available in sizes ranging from 0.5 L to 3,000 L.

Horizontal Mixer

Batch-type powder mixer. Helps improve product yield, particularly for applications that require a clear filtrate; ideal for treatment for which filtering presents difficulties.

Vertical Mixer

Vertical, high-speed batch-type powder mixer; available in sizes ranging from 10 L to 1,000 L.

Reverse Mixer

Batch-type powder mixer; low/medium-speed mixer offering good mixing performance and broad-ranging applicability.

System Mixer

Combination-type mixer comprised of vertical, high-speed heated mixer and cooled horizontal mixer.

Filmix

(PRIMIX Corporeation)

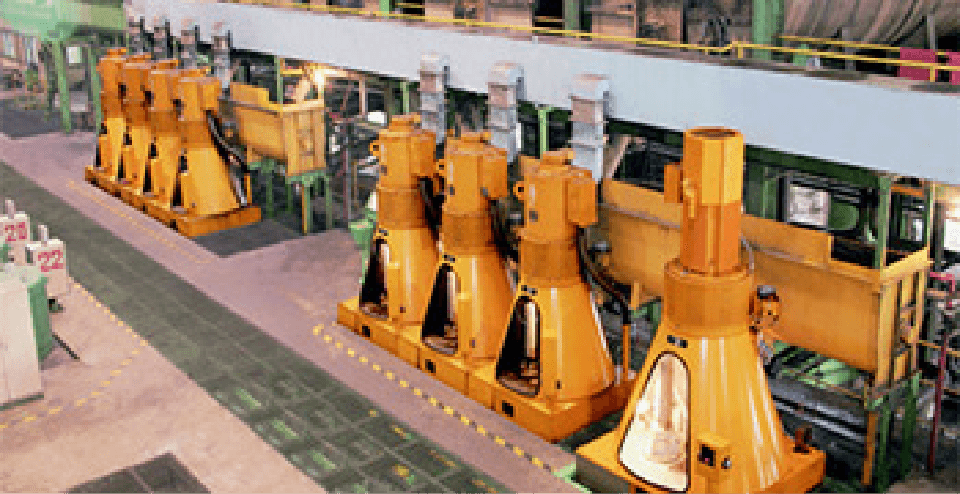

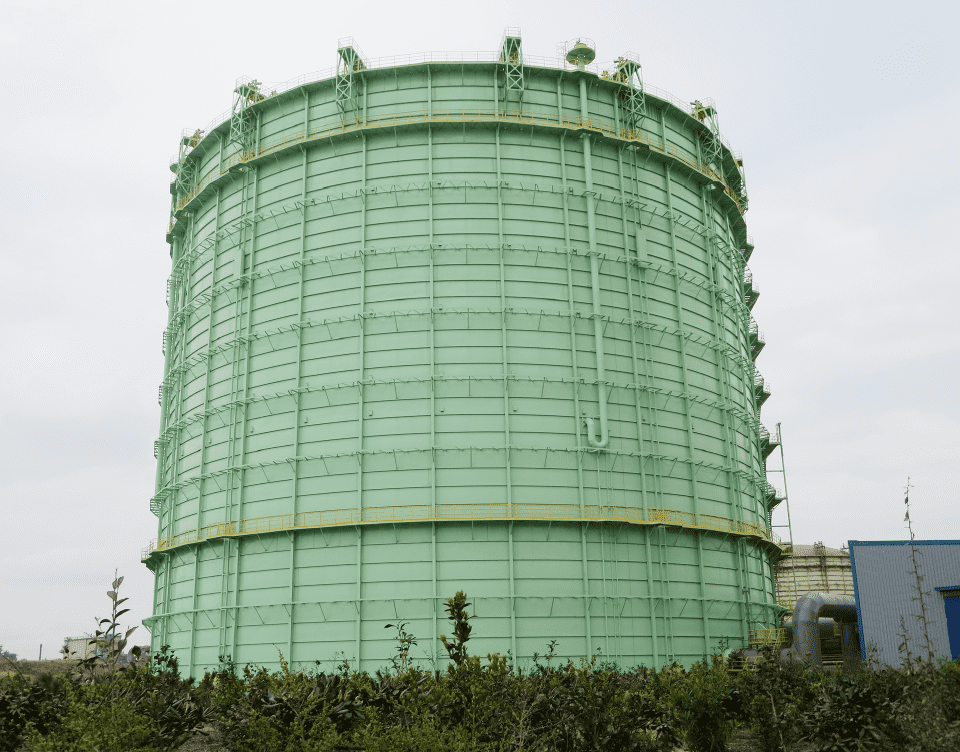

Storage

Storage

Tsukishima Kikai provides storage equipment for various organic gases, primarily in the iron and steel field.

Dry-seal Gas Holder

Vibration

Vibration

Ultrasonic Sieve

Circular vibrating sieve incorporating an ultrasound unit manufactured by Telsonic in Switzerland.

Vibrating Sieve

Ideal for a wide range of applications, including wet or dry screening, solid-liquid filtration, separation, dehydration, recovery, and washing

Vibrating Mill

A vibrating pulverizing mill offering economic pulverization; capable of producing products of uniform particle size.

Vibrating Polisher

Ideal for a wide range of applications, including deflashing, deburring, chamfering, polishing, and descaling with numerous materials.

Vibrating Mixer

New mixer type based on the same vibrating unit used in sieves and polishers for mixing.

Molding

Molding

※ SMC(Sheet molding compound)

SMC

Sheet impregnation

machine

System featuring a standard turning winder and zigzag storage that can be used in conjunction; ideal for use as a sheet storage system for high-volume production machines.

SMC

Sheet storage system

Impregnation machine for use in the manufacture of various SMC sheets requiring uniform, high density glass fiber and resin impregnation performance.

Milling

Milling

Dry Pulverizing Mill :

Cyclone Mill

New, revolutionary type of dry pulverizing mill.

Hemispheric Head

Cyclone Separator

Minimizes raw material losses; produces astounding recovery ratios. The reduced bag filter burden saves maintenance labor and extends service life.