Crystallizer (DP Crystallizer / Oslo Crystallizer)

DP crystallizer

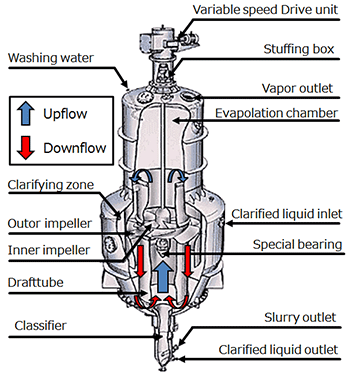

Structure and Principle

The DP(Double propeller) crystallizer was developed as improved model of DTB crystallizer. The crystallizer is equipped a fixed draft tube inside and double(inside and outside draft tube) propeller. The DP crystallizer generates up flow inside draft-tube and down flow outside draft-tube simultaneously by driven by one shaft, so this crystallizer can generate large volume of inner circulation, then can realize ideal mixing condition for industrial crystallization as low rotation speed and larger circulation.

Features

Large circulation volume

The crystallizer creates a favorable mixing condition so as to achieve uniform super saturation which prevent excess formation of crystal nuclei. Thus high quality crystal can be formed, and long period stable operation can be achieved due to minimizing scaling.

Sharp distribution of grain sizes

The crystallizer is enabled to change the circulation volume in crystallizer and adjust required operating supersaturation by adjusting revolution of double-propeller. In addition, double propeller with slow rotation speed strongly restricts generating secondary nucleation without decreasing circulation volume, so the crystallizer can manufacture crystals of required size, whether large or small in diameter, on a sharp grain size distribution.

Certainly scale-up

Operating super saturation is used as a scale-up factor, so reliable scale-up can be done easily.

Fig.1 DP crystallizer with clarifying zone

Applications

【Inorganic chemical】

Ammonium sulfate, Nickel sulfate, Peroxodisulfuric sodium, Alum, potassium chloride Barium chloride, Sodium nitrate, Soda ash, Silver nitrate , Sodium hydrogen carbonate , Potassium carbonate, Sodium Phosphate, Boric acid, etc

【Organic chemical】

Bisphenol-A, Caprolactam, Acrylamide, Hydroquinone, Adipic acid, Ammonium adipic acid Fumaric acid, Trehalose, Aspartame, Amino acid, etc

Oslo crystallizer

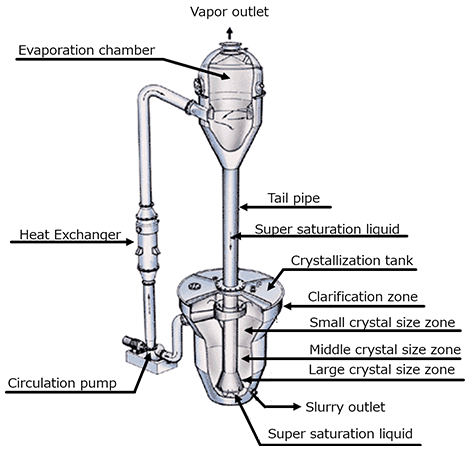

Structure and Principle

Oslo crystallizer has a structure that the evaporation chamber is separated from crystallization tank. The mother liquor which is clarified at top clarification gone of crystallization tank extracted from the small crystallization zone is concentrated by evaporating in evaporation chamber after passing heat exchanger.

A supersaturated liquid concentrated in evaporation chamber go down through tail pipe then is supplied to bottom of crystallization tank. The liquid penetrate fluidized crystal bed and crystals grow by contacting and desupersaturation of liquid.

Features

No mechanical crystal breakup

The circulation pump transfers clear liquid only, producing no mechanical crystal breakup.

Fig.2 Oslo crystallizer

Applications

Ammonium sulfate, Sodium cyanide, Nickel sulfate, Sodium chlorate, Nickel chloride, Copper sulfate

Related field & technology

- Chemicals field

- BPA manufacturing plant

Tsukishima Kikai owns licenses for BPA manufacturing plant and has many track record of EPC.

- Chemicals fieldIron and steel field

- Sulfate Crystal manufacturing plant

Tsukishima Kikai has many track record of for Sulfate Crystal manufacturing plant.

- Crystallization

- Counter Current Cooling Crystallization and Purification process (4C Process)

CCCC Process can perform a high grade purification by combining a melt crystallization using scraped type crystallizer and purification using purification column.

- Chemicals field

- Chemicals manufacturing plant

Tsukishima Kikai has many track record of for chemical manufacturing plant.