Vortex flow crystallizer

CRYSTALLEX Type-VF

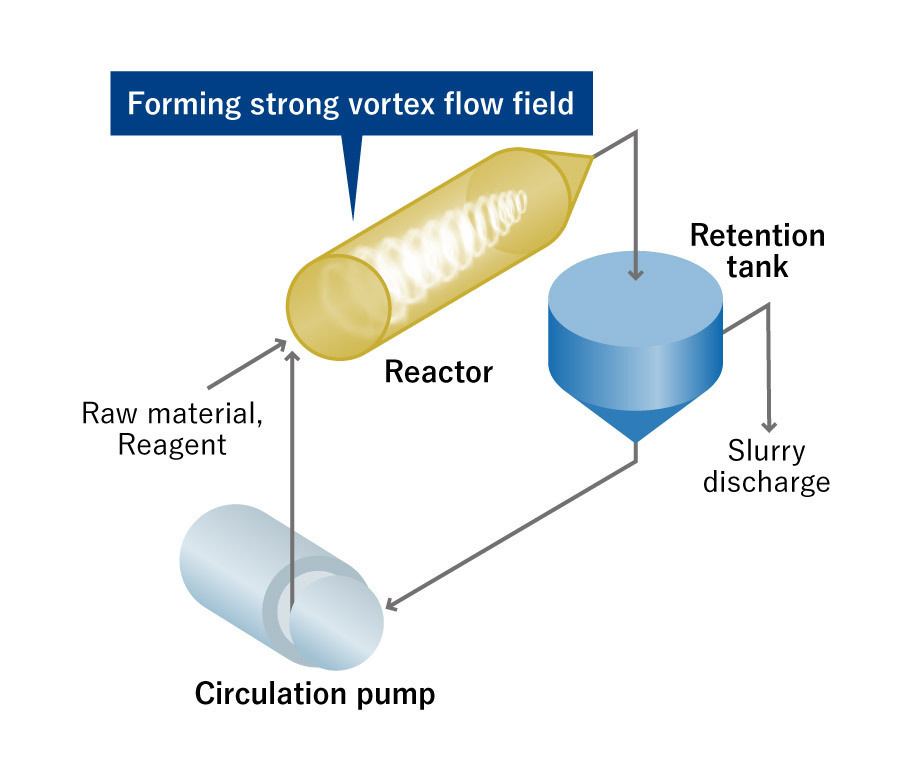

Structure and Principle

This crystallizer creates a strong vortex field for reaction within the reactor by circulating reaction liquid. By the raw material is fed continuously into this vortex field, this reactor enables uniform reaction crystallization in the reactorcontinuously. Therefore this crystallizer can continuously be obtained fine particles.

Features

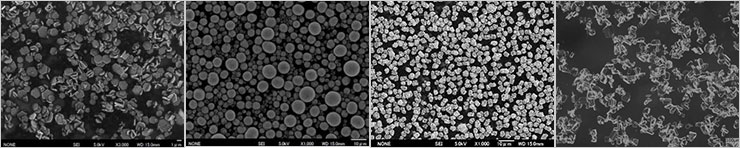

Fine crystal, sharp distribution of particle size

This crystallizer can continuously manufacture fine particles (several µm) with a sharp particle size distribution (close to monodispersity).

High productivity as against volume

This crystallizer volume can be reduced required reaction volume down to 1/10 compared with a conventional agitation tank for same production rate, because high reaction efficiency and continuous production system.

Others

The start-up time is short. As this crystallizer is size fixed unit, production capacity can be easy increased by numbering-up, and its simple internal structure enables easy disassembly and cleaning.

Fig.1 Schematic drawing

Fig.2 Vortex flow crystallizer

Fig3. Example of products

Applications

LiB material, Inorganic material, Cosmetics etc.

Related field & technology

- Crystallization

- DP crystallizer · Oslo crystallizer

Tsukishima Kikai provides optimal crystallization systems and refining apparatuses that are fully compatible with the properties of each substance.

- Energy field

- Precursor manufacturing plant

Tsukishima Kikai provides optimum crystallizer for precursor manufacturing plant.

- Filtration

- Compression blow dehydrator

In the solid-liquid separation of minute particles, this filter can produce dewatered cake having an extremely low liquid concentration.