Counter Current Cooling Crystallization and Purification Process (4C Process)

Structure and Principle

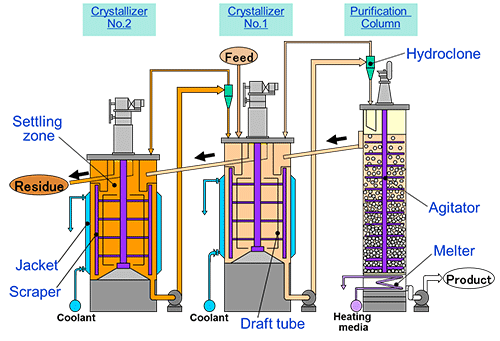

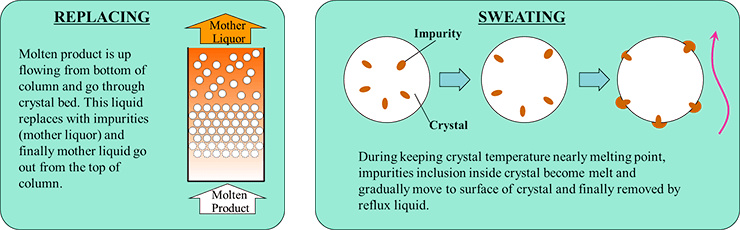

This CCCC(4C) process is an innovative high grade melt crystallization and purifying system, which combines scraped surface crystallizer and purification column, without solid-liquid separation facility. Crystals are produced in the scraped surface crystallizer, and are sent to the purification column to build up crystal bed by gravitational segmentation. Crystals are melted by base heater equipped at column bottom, and a part of molten liquid is withdrawn as product. The rest of molten liquid rises through the crystal bed as reflux liquid and replaces impurities (mother liquor). As crystals are kept slightly lower temperature than melting point of pure product, sweating effect achieves ultra-high purity.

Features

High-purity product

Depending on the characteristics of raw material and the physical properties of impurities, you can generally obtain at least 99.9% pure products. In some cases, a 99.999% purity level has been achieved.

Energy-saving process

The crystallization latent heat is much lower than vapor-liquid latent heat using in a distillation operation. Thus, the crystallization operation can be an appropriate component separation process to produce high-purity product with saving energy. The difference is clearly seen in separation of mixtures having boiling points extremely close to each other and in manufacturing of at least 99.9%-pure products.

High-quality products

Internally running below the melting points of the products, the CCCC process is capable of purified products at far lower temperatures than distillation. The process can prevent the quality degradation of products.

Long-term stable operation

The scraped surface crystallizer used in the CCCC process produces crystals by indirect cooling. A scraper contacts directly to cooling surface to keep surface clean, thus high heat transfer coefficient can be kept for long period.

Fig.1 Typical CCCC (4C) process flow

Fig.2 Principle of purification

Applications

Naphthalene, PDCB, Para-xylene, raw material of LiB, Para nitro chloro benzene (PNCB), Para phenylene diamine (PPDA), Styrene monomer, Acrylic Acid, etc.

Related field & technology

- Crystallization

- DP crystallizer · Oslo crystallizer

Tsukishima Kikai provides solutions for crystallization operations on the basis of its accumulated experience with its proprietary DP crystallizer, Oslo crystallizer, and other models.

- Chemicals field

- PDCB manufacturing plant

The high-quality PDCB manufacturing process combines the technology of Nippon Light Metal Co., Ltd. and Tsukishima Kikai's CCCC process.