Filtering and Drying Machine

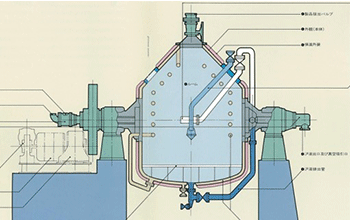

Structure and Principle

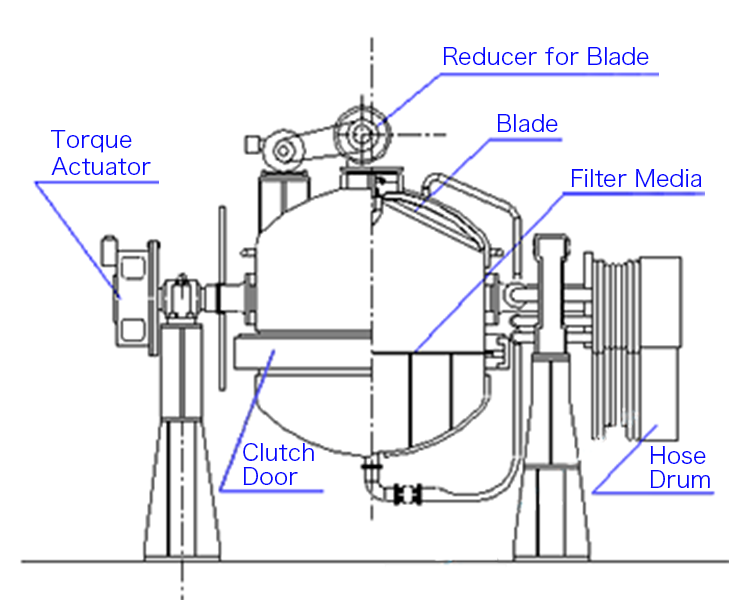

This system performs filtering, cake washing, and drying operations within its airtight structure. A filter material installed within the container performs pressure or vacuum filtering and cake washing. Then, a heating medium is transferred to the container jacket to perform drying.

The container-rotary type of the system rotates the container so as to dry solid product evenly within the container. The agitation-reverse type is equipped internally with an agitator, which performs drying while crushing and agitating wet cake blocks.

Features

Full discharge

The discharge port for solid matter is located at the bottom of the system. Thus, no product residue remains within the container, enabling the full discharge of solid product matter.

Handling multiple processes in a single cycle

Filtering, cake washing, and drying are performed in the same container. This eliminates the necessity of taking any step between such processes. Complicated wet cake processing is also unnecessary.

Free from contamination

As operation is performed within the airtight container, no contamination from outside can occur.

Reversal type Filtering and drying machine

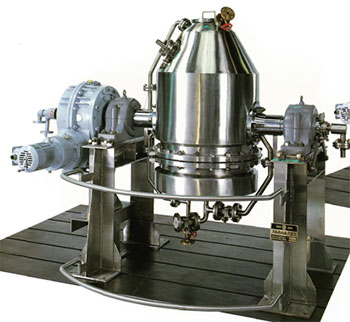

Stirring type Filtering and drying machine

Applications

Medical material, Fine chemical , Electronic material

Related field & technology

- Energy field

- LiB-Precursor manufacturing plant

To avoid the contamination of battery materials, batch processing with a filtering dryer is a good solution.

- Weighting/mixing

- Powder handling system

After undergoing filtering, washing, and drying, products are weighted, mixed, and released via an automated powder handling system.