BoCross Filter

Principle

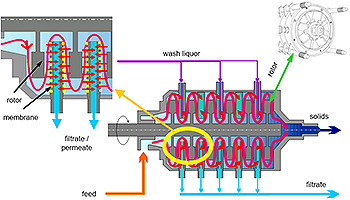

Dynamic crossflow filtration with the BoCross filter enables high concentration, filtration, washing as application for nano-sized particles. Dynamic membrane filtration (BoCross Dynamic) and dynamic sieve filtration (BoCross MicroScreen) can be selected.

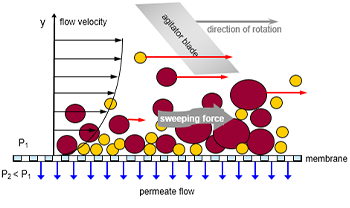

Cross flow (share stress) of the suspension generated by a rotating agitator enables to keep high filtration speed and realizes higher concentration than in case of general cross flow filter.

Features

- High end-concentrations (like firm filter cakes)

- High end-concentration and high washing performance for slurry at solid particles>0.01µm

- High flow rates even with highly concentrated suspensions

- Filtration for high viscosity slurry

- Washing, desalination of mother liquor

- Slimly, jelly smooth particles which are difficult to separate

- Dead end filtration: absolute clear filtrate

- Max. filtration pressure: 0.6MPaG

- Max. operation temp: 100 degree C (normal case), 200 degree C (special case)

- Continuous operation or batch operation can be selected

- Hermetically sealed process

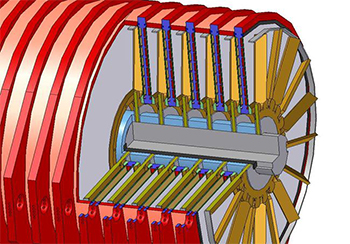

(Section view)

(Exterior View)

(Flow forces on a particle)

(Meander-shaped suspension flow)

Applications

Pigments, dyes, pharmaceuticals, fine metallic powders, titanium oxide, battery materials, polymeric dispersants, cosmetics raw materials, etc.

Related field & technology

- Crystallization

- Vortex flow crystallizer

CRYSTALLEX Type-VF This crystallizer can continuously manufacture fine particles (several µm) with a sharp particle size distribution (close to monodispersity).

- Filtration

- Horizontal belt filter

This filter is a continuous vacuum filter which is specialized in high cake washing performance.