Occupational Health and Safety

Basic concept

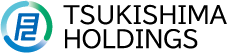

Tsukishima Holdings Group has developed an occupational health and safety management structure based on the international standard ISO 45001. We have established a Central Health and Safety Committee to promote Groupwide activities, through which we strive to ensure safe, secure, and accident-free workplaces at construction and manufacturing sites and elsewhere by formulating site-specific health and safety management activity plans. Health and safety management and promotional personnel are also appointed at Tsukishima Holdings and individual Group companies in accordance with the size and role of each organization, to promote health and safety management and education.

Structure of occupational health and safety organization

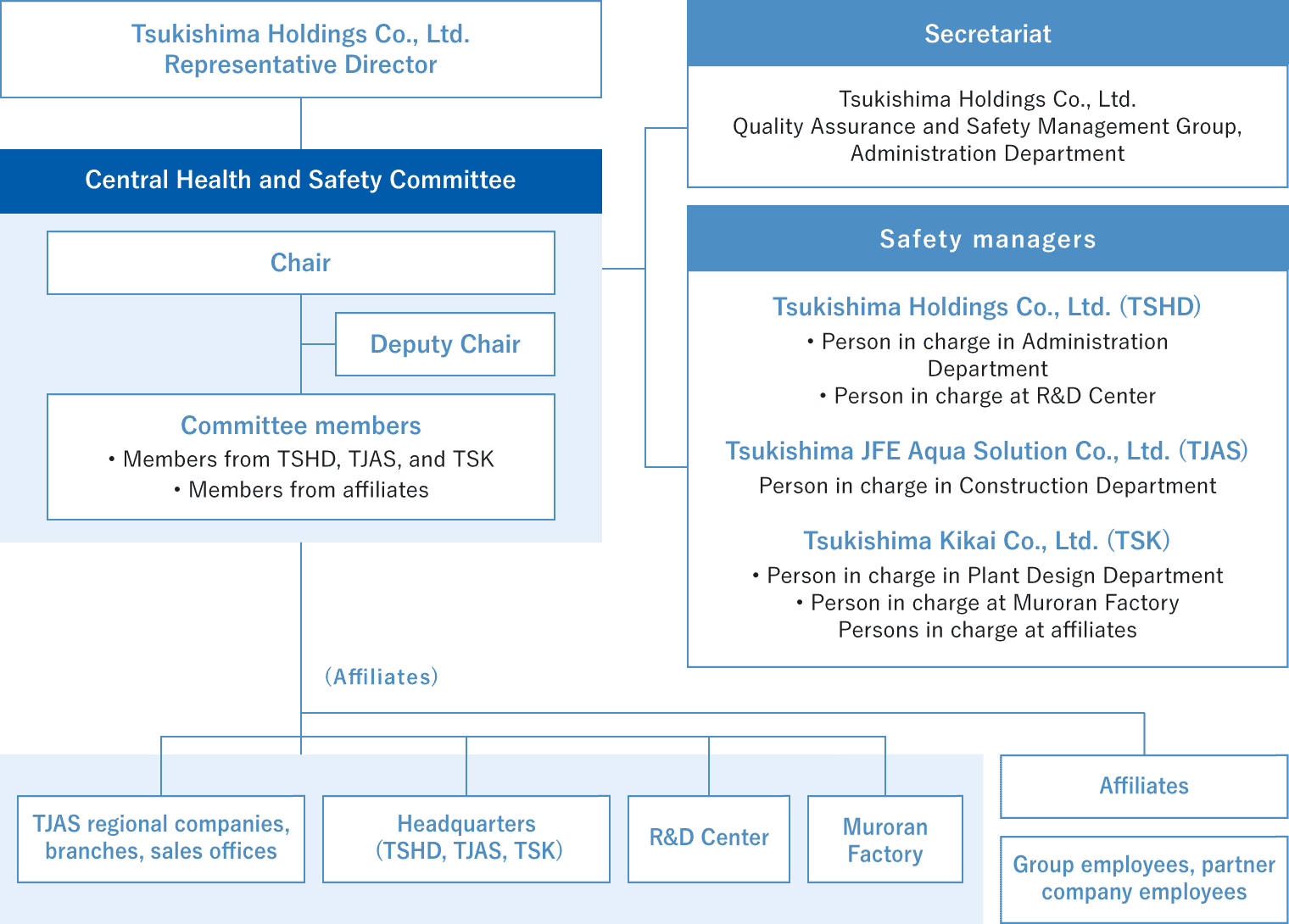

We held our most recent biennial health and safety training program in FY2023. We also hold annual specialized training on tasks involving the risk of oxygen deficiency or presence of hydrogen sulfide, tasks requiring full-harness safety belts, and other topics. Throughout the organization, in addition to sharing information on workplace accidents and implementing accident prevention activities at each site based on Groupwide health and safety policies established by the Central Health and Safety Committee, we carry out quarterly inspections and assessments and make the necessary improvements. In addition, we hold semiannual workplace inspection patrols to inspect and improve workplace environments and post safety slogans, chosen from entries sought from employees, during safety week to raise employee safety awareness. Forty workplace accidents occurred throughout the entire Group in FY2023. In addition to safety education through multilingual videos, we plan to continue enhancing training to strengthen awareness of occupational health and safety via risk assessments based on virtual reality (VR) technologies at Tsukishima & J Technology Maintenance Service and in other ways.

FY2023 occupational health and safety training

-

-

Number of

trainees -

Number of

sessions -

Health and safety training

-

1,446

-

6

-

Special training on tasks involving the risk of oxygen deficiency or presence of hydrogen sulfide

-

48

-

1

-

Special training on tasks requiring full-harness safety belts

-

57

-

2

-

Special training on the handling of low-voltage electricity

-

33

-

1

-

Special training for workers handling dioxins

-

53

-

2

-

Special training for workers handling asbestos

-

46

-

1

Number of workplace accidents

Scope of survey:

Tsukishima Holdings Co., Ltd.,

Tsukishima JFE Aqua Solution Co., Ltd.,

Tsukishima Kikai Co., Ltd.,

Tsukishima Kankyo Engineering Ltd.,

SANSHIN KOGYO Co., Ltd.,

SUN ECO THERMAL Co., Ltd.,

DAIDO CHEMICAL ENGINEERING CORP.,

PRIMIX Corporation,

Tsukishima & J Technology Maintenance

Service Co., Ltd.