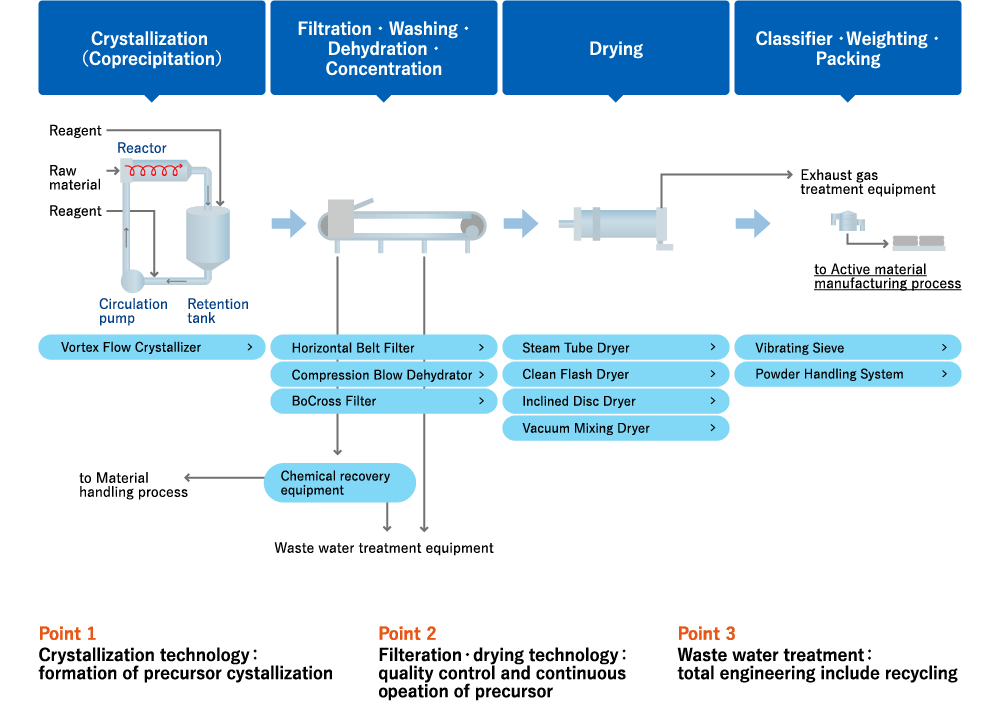

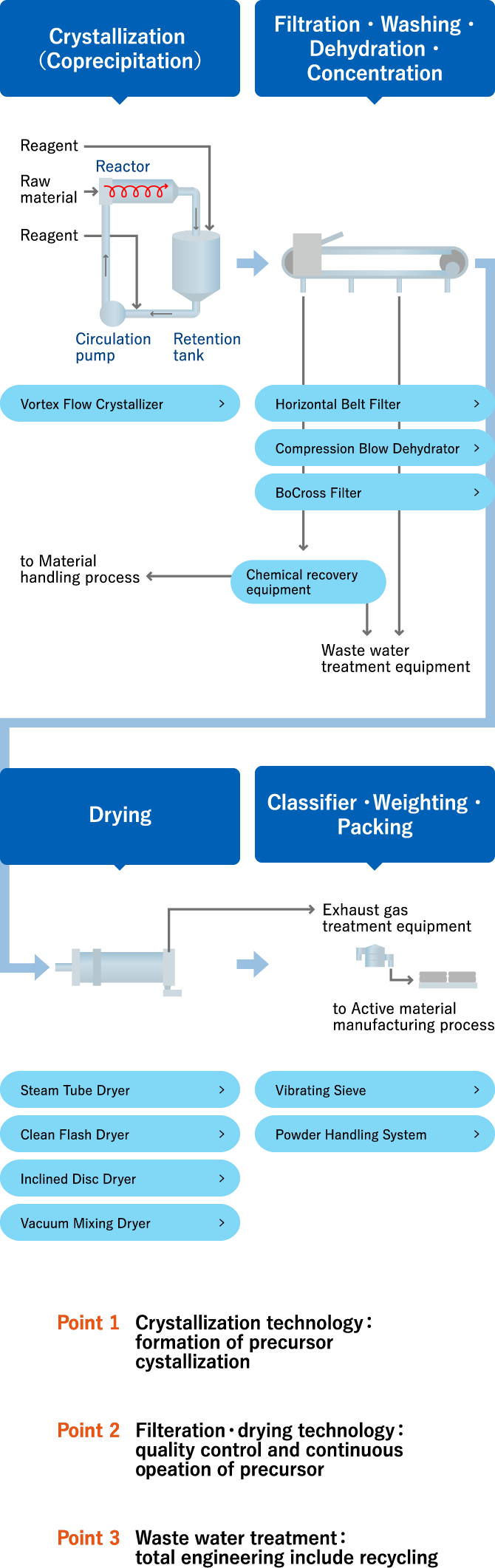

LiB (Lithium-ion Secondary Battery) Precursor Manufacturing Plant

Overview

Our precursor manufacturing equipment is furnished with a reaction crystallizer, a washing & dewatering machine, and a dryer. We also design and fabricate waste water treatment facilities.

Tsukishima Kikai has integrated engineering capabilities for substances ranging from precursors to active material.

Related field & technology

- Crystallization

- Vortex flow crystallizer

CRYSTALLEX Type-VF Ideal for single micron size particle manufacturing. Offers space savings, lower power consumption, and higher yield rates compared to agitation tank types; allows easy scale-up.

- Filtration

- Horizontal Belt Filter

Tsukishima Kikai provides optimal filtration applicable to a wide range of substance properties.

- Filtration

- Compression Blow Dehydrator

This Compression Blow Dehydrator is secondary dewatering system which combined with Horizontal belt filter.

- Drying

- Steam Tube Dryer

Rotary dryer is ideal for large-volume processing. Over 500 units shipped for a broad range of materials, including coal and chemicals

- Drying

- Clean Flash Dryer

This compact vortex-type pneumatic conveying dryer offers ease of maintenance. It can be connected directly to an Escher Wyss Push Type Centrifuge.

- Drying

- Inclined Disc Dryer

This grooved agitation dryer features a special disc construction, making it ideal for highly adhesive materials. Has an extensive track record in sludge treatment.

- Energy field

- LiB (Lithium-ion Secondary Battery) Active Material Manufacturing Plant

Tsukishima Kikai designs and manufactures various equipment for manufacturing active materials as well as provides comprehensive equipment EPC (engineering, procurement, and construction) services.

- Chemicals fieldIron and steel field

- Sulfate Crystal Manufacturing Plant

Tsukishima Kikai has many track record of for Sulfate Crystal manufacturing plant.