BPA Manufacturing Plant

Overview

Bisphenol A (BPA) is a key raw material for polycarbonate (PC), a representative engineering plastic, which is used in a variety of applications, such as optical disks and car components. Demand for this chemical is expected continuous growing in the future. The production process for BPA has been developed jointly with Idemitsu Kosan Co., Ltd.

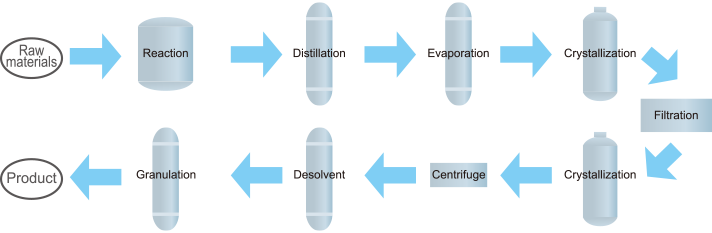

The BPA production process is consists of several steps as shown in Fig.1.

Tsukishima Kikai can design the overall process, and can supply proprietary equipment such as DP(Double propeller) crystallizer, Horizontal belt filter, Escher Wyss push type centrifuge as for key equipment to produce high quality BPA.

Taking advantage of the process and its proprietary unit operation technology, Ten(10) BPA manufacturing plants using this process was constructed over the world and total production capacity is over 1090 KTA. Tsukishima Kikai has long been engaged in the plant construction, equipment delivery, and process licensing of BPA manufacturing process in Japan and abroad.

Fig.1 Process flow of BPA manufacturing

Fig.2 BPA manufacturing plant

Related field & technology

- Crystallization

- DP crystallizer

Tsukishima Kikai provides optimum crystallizer for BPA manufacturing plant.

- Filtration

- Horizontal belt filter

Tsukishima Kikai provides enclosing filter for BPA manufacturing plant.

- Centrifugal separation

- Escher Wyss push type centrifuge

Escher Wyss push type centrifuge is used in BPA manufacturing plant.