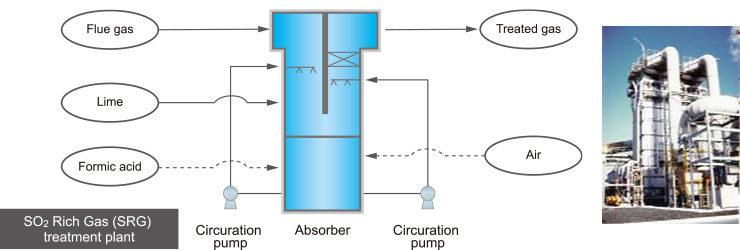

Flue Gas Desulfurization System

Overview

Tsukishima Kikai’s flue gas desulfurization system can handle a wide range of exhaust gases with different properties, such as exhaust gas from heavy fuel oil-/coal-burning boilers, exhaust gas from glass-melting furnaces, decomposed gas from kilns, tail gas from sulfuric acid plants, smelting gas, and condensed exhaust gas from sintering machines.

Japan is the first in the world to introduce the use of flue gas desulfurization system, while demand for such facilities is growing overseas in line with increasing concerns over air pollution. Power plant and other facilities equipped with a flue gas desulfurization system tend to use coal or heavy oil as boiler fuel, which has higher sulfur concentration, for the purpose of saving operation expenses. In addition, flue gas desulfurization systems have become required in recent years to save equipment & operation costs. Tsukishima Kikai has completed more than 100 units of such plants, mainly the lime-gypsum recovery process. We will continue to respond to growing demand for this equipment by taking advantage of our flue gas desulfurizing technologies.

Related field & technology

- Environmental field

- Seawater flue gas desulfurization system

Tsukishima Kikai has most-advanced Flue gas desulfurization technology and many track record.