Sludge Drying Equipment

Overview

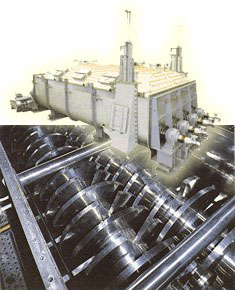

Tsukishima Kikai’s “Sludge drying equipment for industry field” has been used for pulp sludge and various sludge treatment process.

Tsukishima Kikai has been developing solid and liquid separation technologies since its foundation. Such technologies(filtration, separation, drying) are applied across a wide variety of processes.

![]()

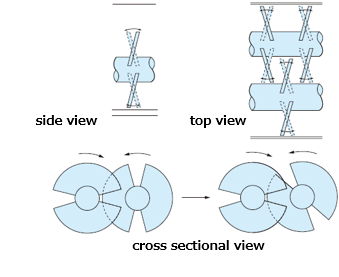

The dryer is indirect heating type composed of the casing with jacket and shaft with disc which contain steam or other heating media. Hollow inclined discs are adopted for obtaining high heat transfer coefficient and raising oscillation effect. As the discs rotate, the dryer has self-cleaning effect to scrape adhered material on shafts, discs and casing off automatically. In this way,the drying performance is enhanced by the prevention of adhesion of material and the renewal of the heat transfer area.

Features

Compact

The heat transfer area by unit volume is large, thus requires a smaller installation space.

Energy-saving

Indirect heating type dryer has high thermal efficiency. Lower rotation of the shaft by improved agitation makes the power consumption smaller.

Easy moisture control

Moisture contents can be controlled by the temperature of the heating media and by the retention time by adjusting the weir height of dryer outlet.

Small amount of exhaust gas

The indirect heating type generates only small amounts of exhaust gas, compact exhaust gas treatment system and deodorization system is applied. In addition, the dryer can perform vacuum drying at low temperatures.

Disc movement

Applications

Sticky material such as sewage-sludge, Starch, Aluminum hydroxide, Magnesium hydroxide, ABS-resin, Polycarbonate, Polyacetal