Blast Furnace / Linz-Donawitz Converter Gas Holder

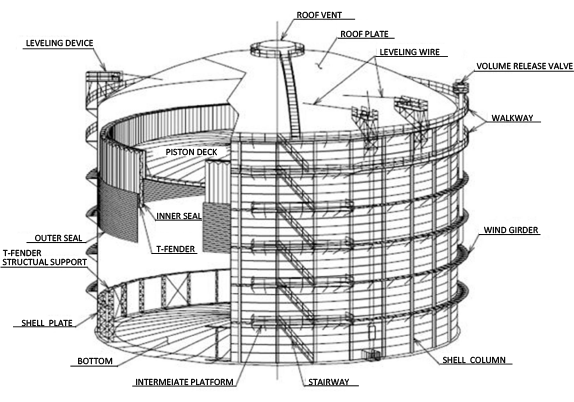

Structure and Principle

This gas holder is composed mainly of a steel bottom plate, side plates, a roof plate, and an internal piston. These components are connected with each other with special seal film to form an airtight chamber. Gas is stored in this chamber under a fixed pressure. Free from friction, the piston moves up and down as the sealing film change its forms. Generally, the pressure of the gas stored in the chamber is 6 kPa or less. For a gas holder having a capacity of 10,000 m3 or more, the side plates support the structure.

Features

Capable of storing water-soluble gas

Not using water, oil, or other liquid in the seal, the dry-seal holder can store water-soluble gas. Also, the gas holder can retain gas containing fine solids such as dust.

Anti-seismic structure

There have been no cases of gas leakage caused by damage to the gas holder due to an earthquake.

Operable for over 40 years

Highly durable and maintainable, our dry-seal gas holder can work for over 40 years.

Outside

Inside

Applications

Blast furnace / Linz-Donawitz converter gas, N2-gas, Desulfurization gas, Helium, Ammonia, Ethylene, Propylene