Compression Blow Dehydrator

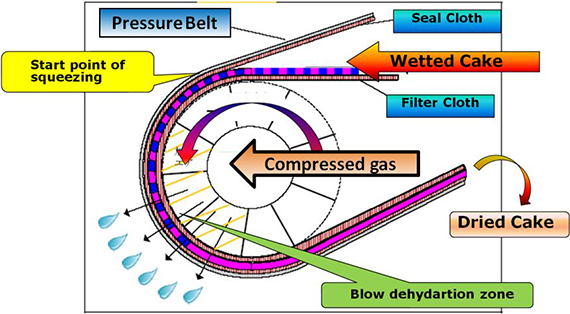

Structure and Principle

Compression blow dehydrator is secondary dewatering system which combined with Horizontal belt filter for further reduction of discharged cake moisture.

This option can reduce discharged cake moisture remarkably especially for fine particle dehydration.

Filtrated and washed cake from Horizontal belt filter is enter into compression blow dehydrator. And product cake is dehydrated by means of squeezing by tension of pressure belt and blowing by high pressure air at blow drum part.

Features

【Outstanding dehydration performance】

Lower cake moisture which cannot be obtained by conventional vacuum filtration or squeezing dehydration can be achieved. This provision will reduce running cost of downstream process remarkably.

【Improvement of wet cake characteristics】

Problem in material handling of sticky wet cake is improved. This enlarges range of choice for downstream process

【Process simplification】

Excellent cake washing performance and dehydration performance can be obtained by one machine with fully continuous operation.

Applications

【Battery materials】

Fine carbon / Raw material of lithium secondary battery

【Dehydration of fine particles】

for less than 30micron (ave.) particles

Related field & technology

- Filtration

- Horizontal belt filter

Horizontal belt filter has extremely high cake-washing capabilities.

- Drying

- Steam tube dryer

Steam tube dryer efficiently dries products after filtering, washing, and dewatering, via continuous indirect heating.