Supplying systems and plant facilities to build more prosperous and more comfortable living and communities

Tsukishima Kikai supplies machinery and plant

equipment used to manufacture a wide range of

materials that support better living,

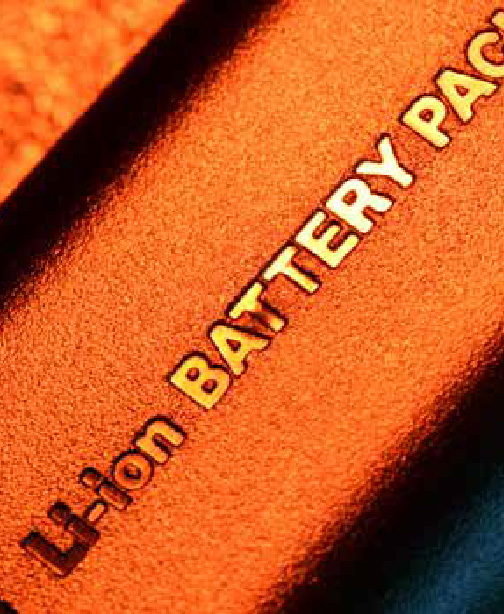

including eco-friendly secondary lithium ion battery materials,

resins used as raw materials for apparel, and sugar essential

to our daily diets.