Sulfate Crystal

Manufacturing Plant

Overview

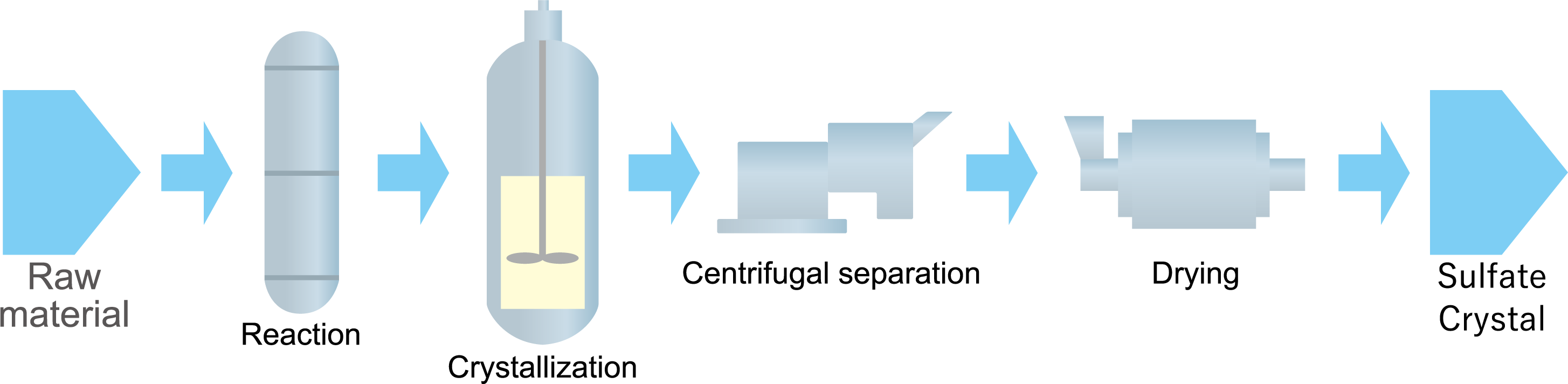

Tsukishima Kikai has know-how for manufacturing several kinds of sulfate crystals. Our Sulfate Crystal manufacturing plant applies a DP (Double propeller) crystallizer or an Oslo crystallizer and, Escher Wyss push type centrifuge and fluidized bed drier or Clean Flash Dryer. Almost 100 plants have been installed delivered during last 60 years.

For ammonium sulfate, Tsukishima Kikai has several processes according to raw materials. These processes are: (a) the recovered ammonium sulfate method, by which ammonium sulfate is produced from sulfuric acid- or ammonia-containing waste liquid from by-products such as acrylonitrile (AN), methyl methacrylate (MMA), and caprolactam (CPL); (b) the by-product ammonium sulfate method, by which sulfuric acid is brought into contact with coke oven gas (COG) or other ammonia-containing exhaust gas, to obtain ammonium sulfate; and (c) the synthetic ammonium sulfate method, by which sulfuric acid is made to directly react with ammonia gas.

As other applications for Sulfate Crystal, Tsukishima Kikai has abundant installation experiences for sodium sulfate, manganese sulfate, cupper sulfate, and etc.

Currently, Tsukishima Kikai’s technology is also used in the manufacturing process of nickel sulfate, which is the raw material for the cathode material of lithium-ion batteries.

Flow of sulfate crystal manufacturing

Related field & technology

- Crystallization

- Crystallizer

Tsukishima Kikai provides suitable crystallization systems that are designed according to each substance properties and various experiments.

- Centrifugal separation

- Escher Wyss push type centrifuge

Escher Wyss push type centrifuge is used in Ammonium sulfate manufacturing plant and for many applications.

- Drying

- Fluidized-bed dryer

Tsukishima Kikai provides dryer applicable to a wide range of substance properties.

- Chemicals field

- Chemicals manufacturing plant

Tsukishima Kikai has a large number of delivery records of not only process equipment, but also entire facilities, as an EPC project.

- Energy field

- LiB-Precursor manufacturing plant

Tsukishima Kikai's technology is also used in the manufacturing process of nickel sulfate, which is the raw material for the cathode material of lithium-ion batteries.